Pipeline Construction

NEXUS Gas Transmission commits great care, thoughtful planning, stewardship and safe work practices to building our network of pipelines. Construction of a new pipeline can involve thousands of workers, tons of high-strength carbon steel pipe and hundreds of pieces of construction equipment. Every step is guided by professionals with years of experience in building natural gas pipelines that meet the highest industry and government standards for safety, environmental protection and operational reliability.

Great effort is taken to minimize disruption to landowners during the construction process. We carefully plan every step of the project so we can install the pipeline and restore the area to its previous use as efficiently as possible.

Pipeline construction is very similar to a moving assembly line, in which several specialized teams are each assigned to perform a single, specific task along small sections of the pipeline. Once each team completes its task, another team follows closely behind to complete the next stage of construction. Once the entire process is completed for each section of the pipeline, the entire process is repeated again for the next section.

The Process Before, During and After Construction

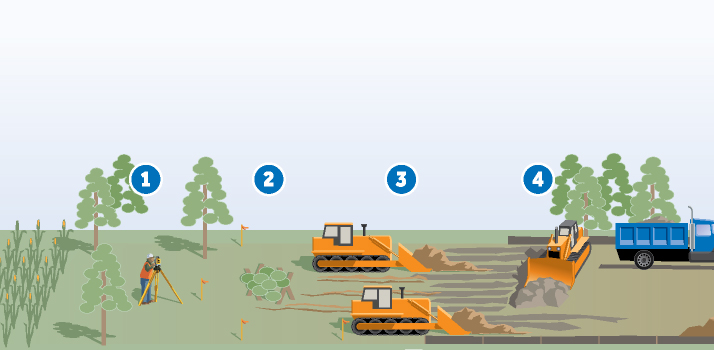

A pipeline construction project looks much like a moving assembly line. A large pipeline project typically is broken into manageable lengths called “spreads” and utilizes qualified contractors. Each spread is composed of various qualified crews, each with its own responsibilities.

To view additional steps below, click and drag your mouse from right to left or click the arrows on either side.

The right of way is a narrow strip of land that contains the pipeline(s) and is where all onsite construction activities occur. Before any construction activities can begin, a survey crew carefully surveys and stakes the construction right of way to ensure only pre-approved construction workspace is cleared.

Clearing is the removal of all trees and brush from the construction work area. Stumps are removed over the trench line and other areas where necessary. Specialized heavy equipment is often used to assist in this process. The stumps are disposed of by burning, chipping and spreading, hauling to approved disposal areas, stored along the right of way with landowner approval or other approved methods.

Grading is required to provide a relatively level surface to allow safe operation of the heavy equipment required to dig the trench and install the pipe.

Topsoil is segregated from the construction work areas in annually cultivated or rotated agricultural lands (except pasture), hayfields and other areas at the landowner's request. To prevent the mixing of topsoil with subsoil, topsoil is stripped from either the full work area or from the trench and subsoil storage area (ditch plus spoilside method). Every effort is made to segregate the entire topsoil layer in soils with less than 12 inches of topsoil. At least 12 inches of topsoil is segregated in soils with more than 12 inches of topsoil. Gaps are left in the topsoil piles to allow water to be diverted off the construction work areas. No topsoil is used for padding over the pipe, to backfill the trench, or for trench plugs across the trench.

The trenching crew typically uses a backhoe or a wheel trencher to dig the pipe trench. Department of Transportation (DOT) requires the top of a pipeline to be buried to a minimum of 30 inches below the ground surface. The pipeline must be buried even deeper at river and road crossings. If large quantities of rock are found during trenching operations, the crew uses specialized equipment or explosives to remove the rock. The crew uses explosives carefully and in accordance with state and federal guidelines to ensure a safe, controlled blast.

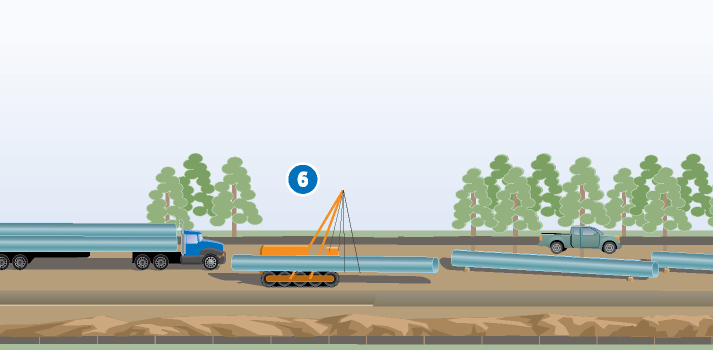

Pipelines are separated into segments typically 40 to 80 feet long. A stringing crew uses specialized trailers to move the pipe segments from a storage yard to the pipeline right of way. The crew meticulously monitors the pipeline design plan to ensure various pipe segments are distributed properly along the right of way because the type of coating and wall thickness can vary based on soil conditions and location. For example, concrete coating may be used in streams and wetlands, and heavy wall pipe is required at road crossings and special construction areas.

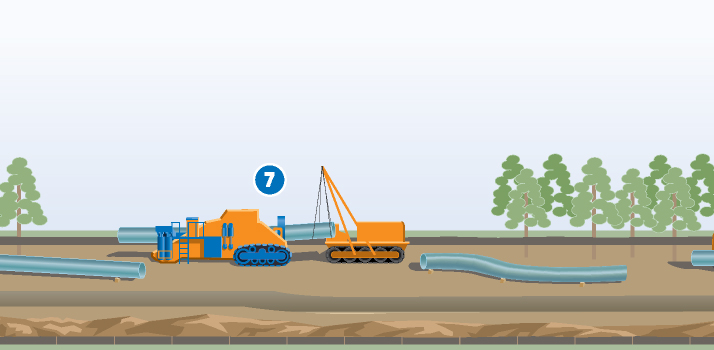

The pipe bending crew uses a bending machine to make slight bends in the pipe to account for changes in the pipeline route and to conform to topography. The bending machine uses a series of clamps and hydraulic pressure to make smooth, controlled bends in the pipe. All bending is performed in strict accordance with federally prescribed standards to ensure the integrity of the pipe is preserved.

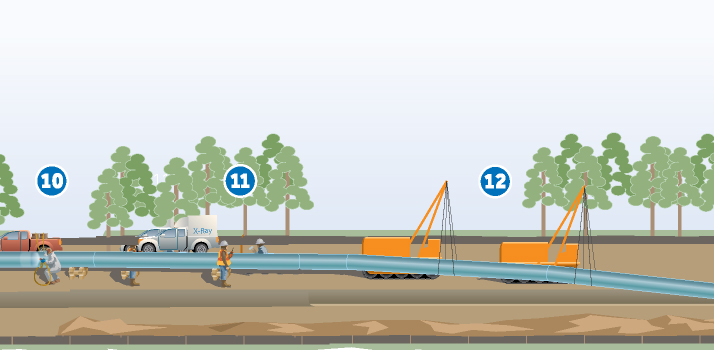

Welding joins the various sections of pipe together into one continuous length. Special pipeline equipment called a sideboom is used to pick each pipe segment and align it with the previous segment. The crew then makes the first part (pass) of the weld. The welding crew follows the pipeline along the route until each segment is welded together. Depending on the wall thickness of the pipe, three or more passes may be required to complete each segment weld.

In recent years, contractors have used semi-automatic welding units to complete the welding process. Semi-automatic welding, done to strict specifications, qualified welders and personnel are required to set up the equipment and conduct hand welding at connection points and crossings.

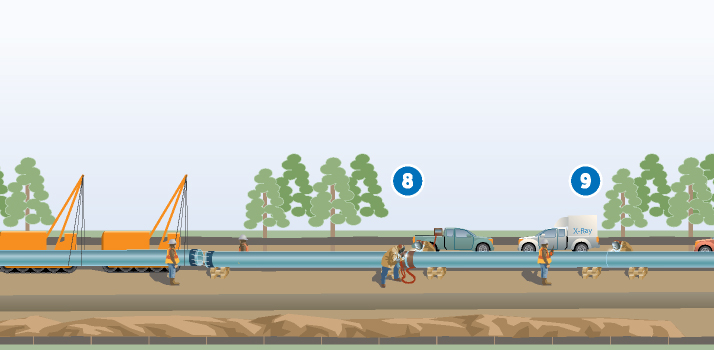

Each weld on the pipeline is made by a qualified welder in accordance with welding procedures and is visually and non-destructively tested (i.e. by radiography and/or ultrasonic) to ensure the integrity of every weld. Welds are inspected and evaluated according to specified welding inspection procedures, standards, codes and drawings.

Pipelines are externally coated to prevent moisture from coming into direct contact with the steel and causing corrosion. This process typically is completed before the pipe segments are delivered to the construction site. All coated pipelines are delivered with uncoated areas three to six inches from each end to prevent the coating from interfering with the welding process. Once the welds are completed, a coating crew coats the remaining portion of the pipeline before it is lowered into the trench.

Prior to lowering the pipe into the trench, specialized equipment calibrated to the proper voltage is used to inspect the pipeline and ensure it is free of defects, known as coating holidays. Experience has shown that under normal field coating conditions holidays rarely occur.

Lowering the welded pipe into the trench demands close coordination and skilled operators. Using a series of sidebooms, which are tracked construction equipment with a boom on the side, operators simultaneously lift and carefully lower the welded pipe sections into the trench. Non-metallic slings protect the pipe and coating as it is lifted and moved into position. In rocky areas, sandbags or foam blocks are placed at the bottom of the trench prior to placing the pipeline in the trench in order to protect the pipe and coating from damage.

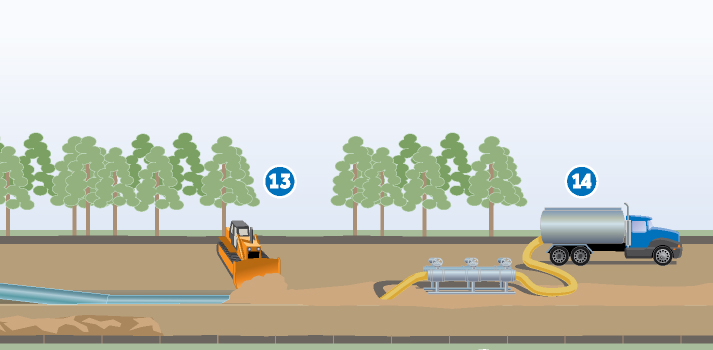

With the pipeline successfully laid in the trench, crews begin backfilling the trench. This can be accomplished with either a backhoe or padding machine depending on soil composition. As with previous construction crews, the backfilling crew takes care to protect the pipeline and coating as the soil is returned to the trench. Soil is returned to the trench in reverse order, with the subsoil put back first, followed by the topsoil. This ensures the topsoil is returned to its original position. In areas where the ground is rocky and coarse, crews screen the backfill material to remove rocks, bring in clean soil to cover the pipeline, or cover the pipe with a protective material to protect from sharp rocks.

Before natural gas is transported through a new pipeline, the entire length of the pipeline is pressure tested using water. This hydrostatic testing is the final construction quality assurance test before the pipeline is put into operation. Requirements for the test are also prescribed in DOT’s federal regulations. Depending on the varying elevation of the terrain along the pipeline and the location of available water sources, the pipeline may be divided into sections to facilitate the test. Each section is filled with water and pressured up to a level higher than the maximum pressure at which the pipeline will operate when carrying natural gas. The test pressure is held for a specified period of time to determine if the pipeline meets the design strength requirements and if any leaks are present. Once a section successfully passes the hydrostatic test, water is emptied from the pipeline and the pipeline is dried to ensure that no water is present when natural gas begins to flow.

The final step in the construction process is to restore the right of way and easement land as closely as possible to its original condition.

Depending on the requirements of the project, this process typically involves such things as replacing topsoil, removing large rocks that may have been brought to the surface, completing any final repairs to irrigation systems or drain tiles, spreading lime or fertilizer. The restoration crew carefully grades the right of way. In hilly areas, the crew installs erosion prevention measures such as interceptor dikes, which are small earthen mounds constructed across the right of way to divert water. The restoration crew also installs riprap, consisting of stones or timbers, along streams and wetlands to stabilize soils. As a final measure, the crew may plant seeds and mulch the construction right of way, to ensure the foliage and grassland is restored as close as possible to its original condition.